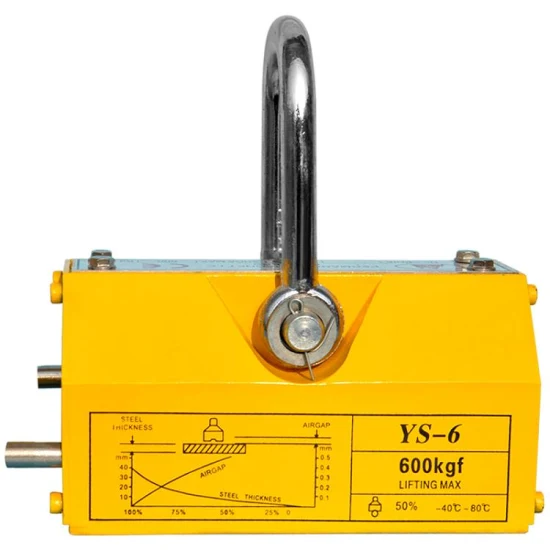

Manual Lifting Magnet Hand Operated Permanent Magnetic Lifter 600kg

Basic Info

| Model NO. | Permanent Magnetic Lifter 2000kg |

| Maximum Lifting Height | 3m |

| Chain Falls | Permanent Magnetic Lifter |

| Certification | CE |

| Condition | New |

| Color | Yellow |

| Product Name | Heavy Duty 2000kg Flat Permanent Magnetic Lifter |

| Capacity | Capacity 100kg, 200kg, 300kg, 600kg,1000kg,2000kg, |

| Usage | Manual Magnet Lifting |

| Safety Time | 2.5time,3time,3.5time |

| Suitable Material | Steel Plate, Pipe |

| Control Method | Manual |

| Working Temp | -10-+80 |

| Material | NdFeB |

| Application of Magnetic Lifter | Industrial Magnet |

| Type of Magnetic Lifter | Manual Lifting Magnet |

| Core Components | Electromagnetic Chuck |

| Feature | High Frequency |

| Sample | Available |

| Delivery Time | 10-15days |

| Quality Test | 100% Tested Before Shipment |

| Transport Package | Carton |

| Specification | capacity 100kg, 200kg, 300kg, 600kg,1000kg,2000kg |

| Trademark | DLZ |

| Origin | China |

| HS Code | 84051190 |

| Production Capacity | 30000 Pieces/Month |

Product Description

Product Description

Manual Lifting Magnet Hand Operated Permanent Magnetic Lifter 600kg

Permanent magnetic lifter can be used in variety of industries for the transportation and lifting of steel, engine parts, semi manufactured goods and moulds, due to its magnetic the surface of lifted goods.

70% for European and the the USA market

More than 10 years manufacturing experience for magnetic lifter Have technique and production advantage for new design

Located near the Tianjin port

Specification:

Name: Magnetic lifters

Range of capacities: 100-6000kgs

Safety factor: 3.5times

Quality standard: CE Detailed Photos

1. Permanent magnetic lifter is widely used as lifting tools in factory terminals and warehouse.

2. Safe and reliable, easy to operate, can be used single or combined with other machines to move long and big magnetic iron steels.

3. Using high-performance permanent magnet, ensure the power and high safety.

4. With a "V" style design at the bottom of lifter, can lift both round steel and steel plate.

5. Maintain constant and reliable magnetism without electricity, residual magnetism approach naught.

6. The maximum pull-off force as 3.5 times as rated lifting force which contribute to improve the working conditions of loading operation and labor productivity.

7. The lifting have high resistance to demagnetization, the lifting value will keep constant and stable.

Model | Rated lifting weight (kg) | Shape Size L*W*H | Max breakaway force (kg) | Net weight (kg) | Gross weight (kg) |

JG100 | 100 | 24*16*16 | 300 | 3 | 3.7 |

JG400 | 400 | 32*20*17 | 1200 | 9 | 10.5 |

JG600 | 600 | 37*23*21 | 1800 | 20.5 | 22 |

JG1000 | 1000 | 43*28*24 | 3000 | 37 | 40 |

JG2000 | 2000 | 52*30*31 | 5000 | 69 | 73.5 |

JG3000 | 3000 | 60*30*31 | 7500 | 89 | 94 |

JG4000 | 4000 | 68*30*41 | 10500 | 113 | 121 |

JG5000 | 5000 | 73*40*48 | 15000 | 202 | 213 |

Production of Permanent Magnetic Lifter

FAQ

1.

Q: Are you a factory or a trading company?

A: We are a factory. We specialize in producing all kinds of Lifting crane, such as mini electric hoist, electric winch, hand pallet truck, manual hand stacker, electric chain hoist, and stainless steel hoist for more than 10 years.

2.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Baoding City, Hebei Province, China, About 1 hours' drive from Beijing. All our clients, from home or abroad, are warmly welcome to visit us.

3. Q: Can you do OEM?

A: Yes, we can do OEM products. Any customized size, packaging and logos are welcomed.

4. Q: How do you control your quality?

A: Quality is priority. Our factory people always attach great importance to quality controlling from the very beginning to the very end:

(1). All raw material we used are environmental-friendly;

(2). Skillful workers care every details in handling the producing and packing processes;

(3). Quality Control Department special responsible for quality checking in each process.

Production process standardization, process standardization, refinement.

5.

Q: What are your advantages compared with others?

A: ISO Quality Management System Certificated Factory:

(1).BV, SGS Field Certification and Assessed Factory

(2). Focused on rigging since 2003, Rich experience in Production.

(3). Owned factory, the same quality product, the best price.

(4). Timely Delivery with the support of 3000 square meter warehouse.

(5). Numerous Patents in Rigging Hardware. Be Good at Custom-Made and Shaped Products.

(6). Over 20 Professional Staff in Trading Team, Let's enjoy worry-free and effective communication.